Founded in 2001 and a fully-owned subsidiary of Arabtec Holding PJSC, Emirates Falcon Electromechanical Company (“EFECO”) is one of the region’s most sought after and respected MEP contracting companies, with the resources and know-how to complete the most technically demanding building projects, no matter what size or complexity.

And because EFECO is fortunate enough to boast some of the most experienced people within the building services industry, it can offer all mechanical, electrical and plumbing services in one works package. What’s more, because it is part of Arabtec Holding, the company can provide unparalleled reassurance, transparency and financial stability.

Many people believe that EFECO is a part of Arabtec Construction; in fact, both businesses are subsidiaries of Arabtec Holding. Nevertheless, Arabtec Construction is one of EFECO’s key clients, with Gavin Appleby, Managing Director, EFECO, explaining that although the two companies do work together on many projects, Arabtec Constructions has quite a number of ongoing projects across the UAE where EFECO is not the MEP contractor: “Both EFECO shareholders and the management are supporting and encouraging us to grow operations outside of the group. We will always have a part to play in Arabtec Construction. There is no doubt about that. But we are very much independent.”

It should also be noted that because the company’s personnel work in a collaborative environment, it enables them to go that extra mile on projects. This is achieved by constantly striving for quality and following trusted processes that help the entire team work efficiently. No one lets obstacles or excuses keep them from meeting deadlines either, with everyone fully understanding the goals and challenges set forth before them. This is fuelled by the fact that EFECO takes the time to discuss project goals. It listens proactively and asks questions, making sure that it understands the client’s precise needs. Subsequently, the company works out a strategy with the client to complete the project within a pre-agreed budget and on time. In effect, EFECO becomes the client’s partner.

Sticking to a Plan

EFECO stands out from the competition in several welldefined ways, not least in that it has very effective risk management processes in place that allow it to ascertain the correct projects to take on, as well as identifying risks at an early stage. The company also has rigorous estimation processes that help to make sure what it is doing and what it is estimating are aligned with market norms and backed up by reliable data.

This derives from the fact that the Arabtec Holding PSJC and its subsidiaries, including EFECO, put into practice a formalised Four-Gate Tender Approval process that allows for enhanced control of all risks related to commercial and contractual agreements and, as a result, project execution. This compulsory course of action means that the company can optimise commercial costs, and in doing so support a tender decision-making process based on objective risk information and the ability to ensure that contractual commitments are in line with its aims and its position on risk.

“When we talk to someone, and if we commit to a price and project timeline, we can deliver the project because we have studied it,” explains Appleby. “We are measuring everything on a project right from material, labour, time and cost, which allows us to assess our projects at any time.”

The EFECO team also understand that material wastage is widespread in today’s marketplace, which is why the company has developed practical procedures for controlling materials. Because of modularisation (which drives efficiency right through the business, increases productivity on projects and accelerates the construction process because MEP elements are already prepared, designed and ready for assembly in the workshop before construction begins), something that is at the heart of a number of EFECO’s current projects, there is a meticulous control of material usage, which helps to do away with significant storage of materials onsite.”

Of course, an MEP contract is not just about buying the right materials and then throwing manpower at it. A detailed plan is required every step of the way, with a focus on attention-to-detail. “Everything has to be measured, and if you measure you know your end result. What we have at EFECO is a very articulate team from project level through to the directors who completely understand and live by a plan’s rules,” says Appleby.

25 Million Man-Hours without LTI’s

EFECO recently completed 25 million man-hours without a lost-time incident, with an excerpt from Lloyds Register Audit Report reading: “Company has shown noticeable performance achieving zero LTI’s for the past two years. Those achievements could not be possible without commitment and implementation of health and safety management system that really supports company’s business goals and reflects on company’s reputation”.

“This milestone demonstrates our dedication and unwavering commitment to health and safety. Such an achievement reflects the successful outcomes of our robust risk management approach which puts health and safety at the forefront of our operations. Combining these tools with the dedication of each of our employees and contractors enables us to empower our team to deliver operational excellence with the highest standards,” Appleby said.

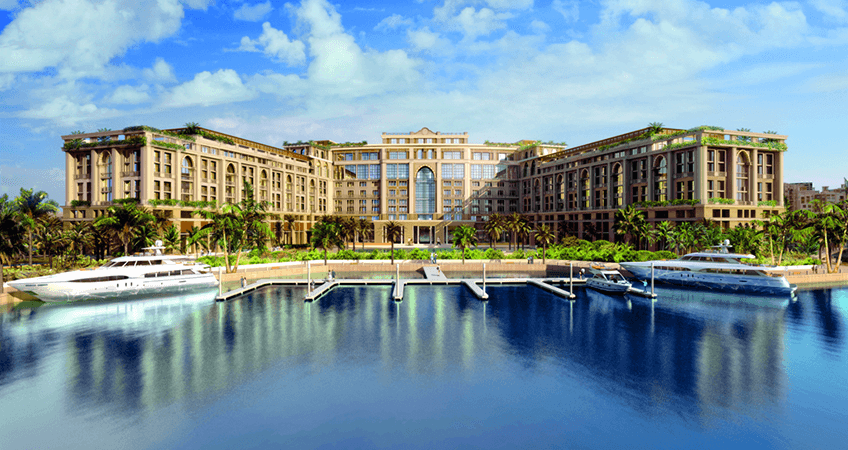

THE CONRAD HOTEL, DUBAI

NATION TOWERS, ABU DHABI

Integration, Collaboration and Cash Flow

One of the biggest challenges in the industry is cash flow, with good cash flow management being vital to the ongoing success of any business. Indeed, even profitable companies can fall short if cash flow is managed the wrong way. However, at EFECO cash flow is just one avenue that needs to be addressed, with Appleby continuing: “I believe beyond cash flow one of the biggest issues in the MEP market is cost control. One big problem is dealing with clients that have financial issues. If you control your costs, you can take the edge off the issue to a certain degree. That’s why my first priority is the control of costs. If you move beyond control of costs, the other important thing that the market has forgotten is about applying technical and engineering capabilities. If you think seriously about it, an MEP business is an engineering business. Everything we do has an engineering component to it and, over the years, I have seen that this seems to have been lost in the race to win contracts. This is something that the sector badly needs to address.

“The sector also needs to embrace better integration. And that means the complete supply chain of a project, and that has simply not happened. This is why MEP contractors are suffering. Integration can be carried out in a lot of different ways. You can integrate at an early stage of a project or at the main contractor level. You can also integrate at a client level if you want; I think there needs to be more value given to what an MEP function can bring to a project.”

At the present time, price wars are also common in the market, a problem that is being exacerbated by the number of new MEP players. And if that were not enough, many of the new players do not appear to understand the market. With a very traditional base of contractors, which all of the established firms know, there are a set of rules that all contractors work towards in regards to execution and professionalism. This naturally adds significant value to a project.

Furthermore, since MEP consultants form part of the wider construction industry, there needs to be improved collaboration. “As MEP contractors, apart from our own labour, our number one partner is our supply chain, and the market supply chain is very distressed at the moment due to lack of payments across the MEP sector. One thing we are working hard with our supply chain on is to ensure that we make timely payments. We don’t want to see any of our suppliers hurt and we are working hard to try and correct that, but it’s very difficult at times to understand,” Appleby explains.

He goes on to give his views on how improvements could be made in the industry, suggesting that there should be some kind of regulatory control of payments: “In mature markets they have such a system and it forces payments to come to contractors and sub-contractors; and there’s a regulatory framework around that. If this was implemented into this market, it would probably improve the overall delivery of projects throughout region. There is a lot of tension between consultants and contractors too, and that’s not good for anyone. In fact, it’s detrimental to projects, not to mention the market and industry in general,” Appleby states.

Client Service is a Passion

Throughout 2017, EFECO went through a re-building process, which allowed the company to return to its grassroots. This has helped it to enter 2018 with exceptional project execution and manufacturing capability across both ductwork and prefabrication. This ongoing success has benefitted from the company having a mix of business, both inside and outside of the Arabtec Holding PJSC group of companies. Moreover, it has mitigated several risks and has a number of Tier 1 contractors that choose to work with it. In addition, EFECO is a company with one eye very much on the future and is investing time and money in the very latest technology, something that many of its competitors are shying away from.

At EFECO, though, technology is the only route forward, with Appleby concluding: “Our one and only focus is to successfully deliver an MEP project using better technology and innovation. The advantages of this are not just to us as an MEP contractor, but also to clients and the contractors that are constructing the building. Anything that we can do to make a project more seamless, aid the progress, provide assurance, ensure visibility, particularly for the contractor we work with, is a big advantage to everyone. We are very much focused on that.”

EFECO is dedicated to client service with the entire company committed to delivering expert MEP project solutions. EFECO takes pride in re-defining the value in MEP services and uses the latest technology to stay on the cutting-edge of sustainable design practices with vast expertise across an extremely broad range of challenges.

EMIRATES FALCON ELECTROMECHANICAL COMPANY (EFECO)

P.O. BOX 42661

DUBAI

UAE

T: +971 4 356 9000

E: ESTIMATION.DEPT@EFECOUAE.COM

W: WWW.EFECOUAE.COM

W: WWW.LINKEDIN.COM/COMPANY/EFECO