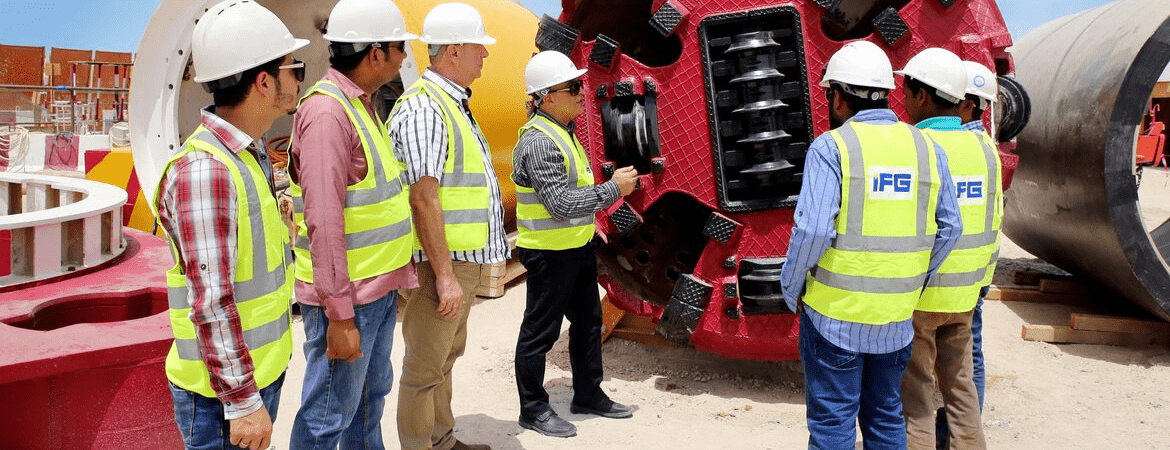

Foundations and tunneling works in the UAE have been transformed by the arrival of International Foundations Group (IFG), under the leadership of Dr Khalil Charif . With foresight and an appetite for engaging in challenging projects, without reservation, IFG is making inroads in all areas and going ‘where other mortals are afraid to tread’.

For example, take the recently completed project in Dubai International Airport, where IFG completed installation of a 3.0m diameter storm-water main for the main contractor, MA Kharafi, under active taxiways without affecting a single flight or a single passenger.

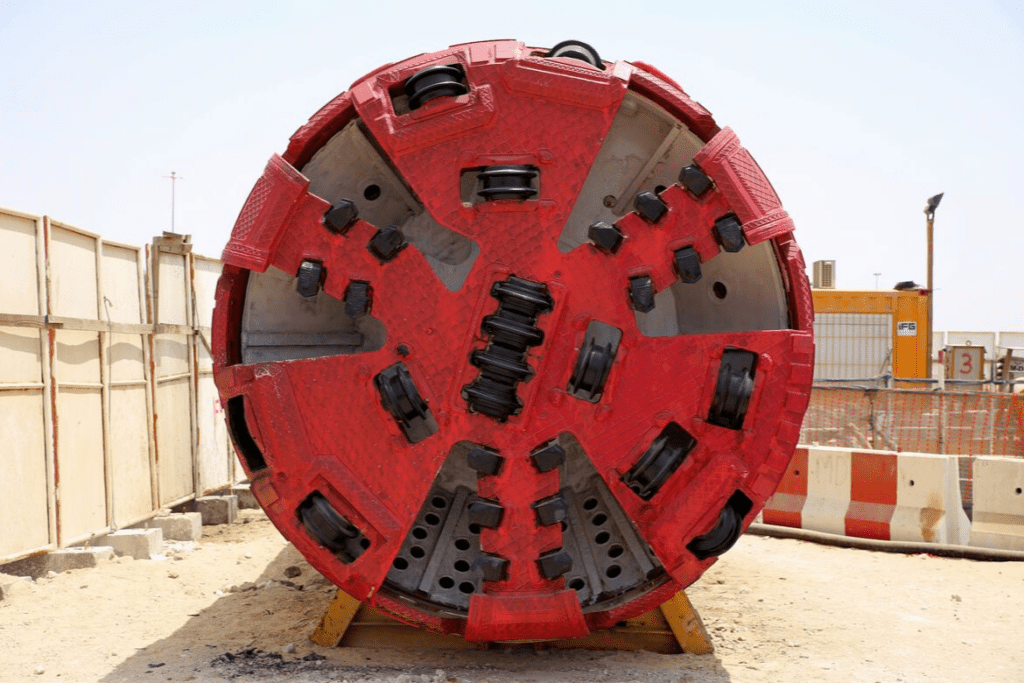

Quickly and safely crossing under airport taxiways and runways is one of the supreme disciplines of mechanised tunneling, especially when flight operations cannot be interrupted. Heave, settlement, or other impairment of this sensitive infrastructure must always be avoided. Herrenknecht tunnel boring machines and BAUER MAT Slurry Handling Systems, in the hands of skillful tunnel builders such as IFG, are ideally equipped for this delicate task.

Dubai International Airport handles the highest number of passengers worldwide – nearly 90 million per year – and is the hub of air traffic in the Arabian Gulf. The operators are constantly investing in capacity expansion.

As part of Dubai International Airport Expansion Phase 3, Herrenknecht’s AVND2400AB excavated three (610, 765, and 825m long) sections for a new storm-water drainage tunnel. At depths of 13 to 15m, using the pipe jacking method, the machine crossed under the Terminal 2 taxiways while flight operations continued uninterrupted. On the longest drive an average of 15m of tunnel with an inside diameter of 2,400mm were built per day.

The new pipelines will have an important role to play: they provide sufficient capacity to quickly drain away the water, even in heavy storm rainfall, obviating all risk of ponding and standing water, which is crucial to maintaining smooth flight operations.

IFG has been responsible for providing foundations for a broad portfolio of prestigious projects: Dubai Opera, Forty Towers, Downtown Dubai, Meydan Racecourse Grandstand, Boulevard Heights, Rosemont Hotel, The Address at Harbour Point, and … the list goes on.

Under an Abu Dhabi sewerage scheme, for instance, IFG constructed pits and shafts up to 80m deep and 50m diameter using a combination of diaphragm walls and secant piles. IFG followed this up with the installation of 50m deep and 3.0 metre diameter sewers.

All of this work was made possible by the continuous support of IFG’s principal equipment supplier, BAUER Equipment Gulf, which has provided all of IFG’s 23 piling rigs and diaphragm wall excavators.

Diaphragm wall construction and micro-tunneling rely also on separating gravel, sand, and fine soil from the slurry produced in these operations, and such sand separation is achieved in all cases by employing sand separation units from BAUER MAT Slurry Handling Systems and Schoenberg.

IFG employs industrial professionals and provides state-of-the-art expertise in:

- Main foundation works, using conventional bored piles up to 1.8 metres diameter and CFA cased and uncased piles, using, for example, its BAUER BG39 with double rotary head

- Construction of shafts up to 80 metres deep using secant piles and diaphragm walls

- Construction of basements using diaphragm walls and tied-back secant and contiguous piles; the tie-back anchors are drilled with IFG’s state-of-the-art equipment from KLEMM Bohrtechnik, which is a member of the BAUER Group

- Ground improvement, stabilisation and cavity filling by drilling and grouting

- Slope stabilisation

- Ground anchors

- Micro-tunneling with a range of Herrenknecht tunnel boring machines from 400mm to 3.6m diameter

IFG’s trusted piling equipment is largely sourced from BAUER and from Schlumberger and, having BAUER’s undivided support in the sales and aftersales division, IFG is confident of quickly and successfully completing any piling or diaphragm wall work assigned to it.